SPS Stage Bangkok offers a unique opportunity to connect with potential partners and customers in the Thai market through seminars and exhibitions at Automation Thailand and Intelligent Asia Thailand.

About SPS Stage Bangkok

Built on the strong foundation of SPS Nuremberg, a global stage for innovation in production, SPS Stage Bangkok brings the latest automation trends and solutions to the ASEAN market. The programme highlights how emerging technologies are transforming industrial production.

The Bangkok event combines live demonstrations with practical seminar content, creating a focused environment for solution providers to present real-world applications and engage directly with industry professionals seeking smart production solutions.

Strategic Exposure and Industry Engagement

SPS Stage Demo Pod: Interact and engage with industry professionals at a dedicated demo pod, build relationships face-to-face.

SPS Stage Seminar Stage: Speaking opportunity to share insights and expertise on automation trends with key decision-makers. Chance to educate and influence the audience through thought leadership.

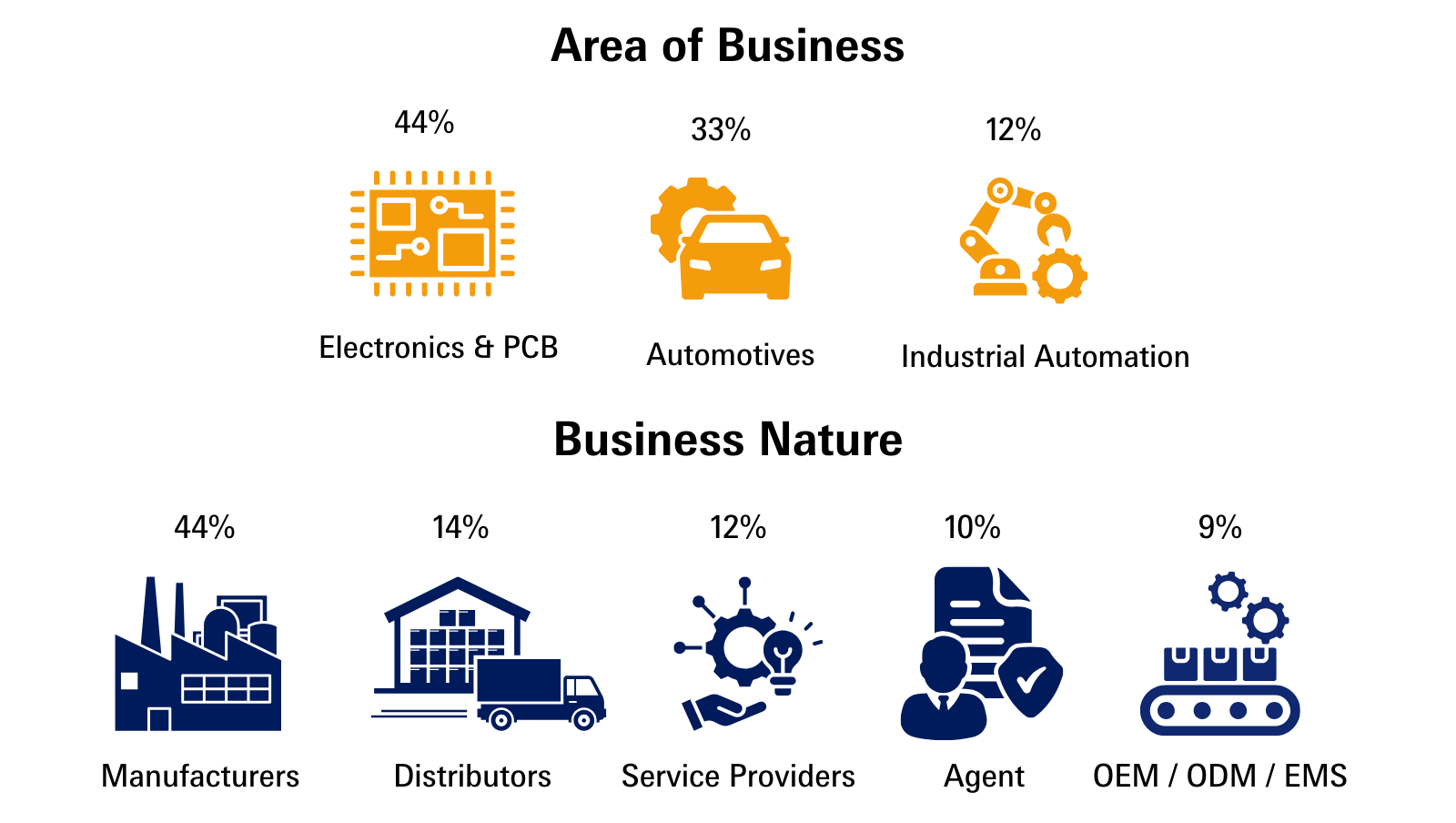

Who Will You Reach?

The seminar program is meant for a highly targeted and influential audience, ensuring your message reaches the right person.

*Percentages indicate the share of visitors

Why Exhibit at SPS Stage Bangkok

Joining SPS Stage Bangkok is more than just a marketing opportunity - it’s a strategic move to position your brand as a leader in automation.

- Lead the Conversation: Share your expertise on industry-critical topics and establish thought leadership

- Boost Your Brand: Show the market how your solutions drive efficiency and innovation. Gain visibility among top professionals and decision-makers.

- Connect with Innovators: Network with Industry leaders, potential customers, partners, and experts to build relationships that can transform your business in Thailand and beyond.

- Benefit from Dedicated Marketing: Leverage our extensive marketing efforts to attract attendees.